The sixth edition of sourcing fair Texhibition Istanbul took place from 11th to 13th September 2024 at the city's exhibition centre near Atatürk Airport. All three days were well attended - according to official figures, almost 24,600 trade visitors attended; about the same number as at the March edition. A good 25 percent of (6,488) came from abroad, a large proportion of them buyers from international brands such as Alexander Wang, American Heritage, Asos, Calvin Klein, Derek Lam 10 Crosby, Esprit, Forever 21, Sainsbury's, Uncle Studios and Veronica Beard. A total of 117 countries were represented, including the European Union, UK, USA, Canada, South America, Asia, North Africa and the Middle East.

Since its first edition in March 2022, attendance at the fair has steadily increased - despite the impact of last year’s devastating earthquakes - from 11,000 visitors in its debut year to 20,000 visitors in 2023 and around 25,000 visitors in 2024. The plan of the organisers - the Istanbul Textile and Apparel Exporters' Association (İTHİB), a member of the Turkish fashion and textile association İTKİB, worked out: halls were added year after year, thus increasing the number of exhibitors.

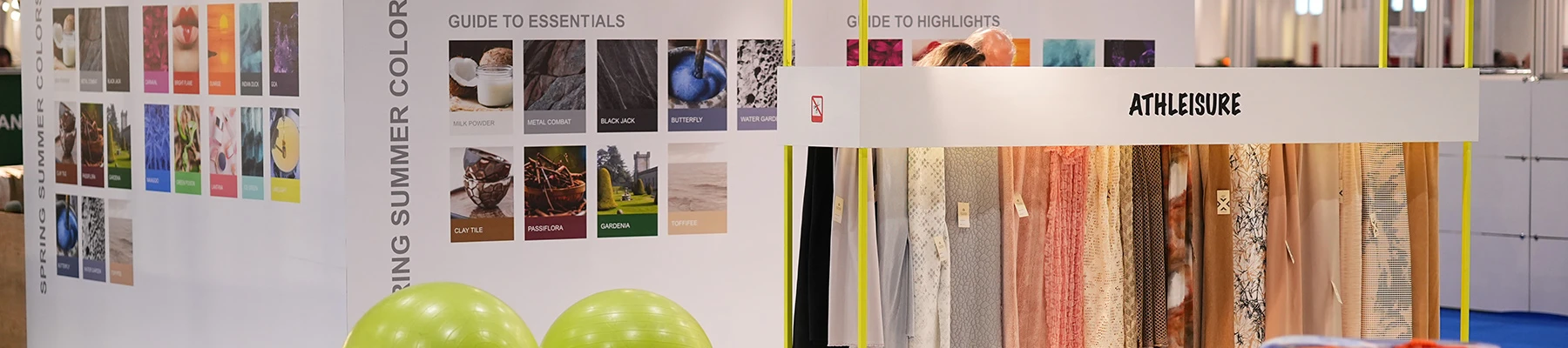

The fair started in 2022 with one or rather two halls by the second edition and already expanded to three halls and around 440 exhibitors in 2023. Yarn and denim manufacturers were initially included with other segments but are now housed in their own halls. This year, the number of exhibitors rose to 539 and an area of 35,000 square metres - a wide selection of woven fabrics, knitwear, denim, accessories, prints and yarns was presented in five halls.

In addition to established companies such as Almodo, Bahariye, BTD, Can Textile, Iskur, Kipaş, Migiboy, Menderes, Söktaş, Yünsa, Zorluteks and İpeker, numerous other high-performance, export-oriented companies from the woven and knitted fabric sector presented their latest products. Hall 8, for example, showcased yarn and fibre manufacturers such as Diktaş, Ensar, Karafiber, Korteks, Sasa and Tepar.

Expansion and challenges

Not only attendees have to wait in line at Texhibition, exhibitors too. “We currently have a waiting list of 700 to 800 exhibitors. While there are 20,000 manufacturing companies in Turkey and 13 halls available here on site, we don't want to go big all at once, but level up slowly”, explains Kemal Özhaseki, board member of İTHİB and Haseki Tekstil, at a press conference.

When asked about international exhibitors (there are currently a few), Özhaseki stresses that those who have long-standing business relationships with Turkey are of course welcome, but that Texhibition was primarily conceived as a trade fair for Turkish manufacturers who do not visit European equivalents such as Premiere Vision or Munich Fabric Start.

Of course, there are also challenges to overcome. While 70 to 80 percent of the companies affected by the earthquakes have recovered, the cities in the affected areas have not yet - construction and reconstruction work is continuing here, especially residential buildings, as many people are still living in temporary accommodations or have had to leave the region.

Another problem for the Turkish economy, high inflation, is slowly abating and is taken in stride. “Türkiye has lived with inflation before; so we know how to deal with it and how to protect ourselves,” says Özhaseki confidently. And indeed, there is a buzz of activity and a generally positive atmosphere in the halls of Texhibition that seems to defy the world's problems.

Innovations and denim

Versatile textile innovations are doing their part to keep it interesting. The Innovation Hub was designed this time by designers Arzu Kaprol and Filiz Tunca. Among other things, they presented a fibre optic dress using the luminous DreamLux fabric. Such fabrics can be used in areas such as home decor, outdoor, event design and wearable tech. Also on display were a carbon-heated poncho and cushions that can be heated to a desired temperature by a heating system woven into the fabric.

The Texhibition Trends Areas were designed by designer and creative director Idil Tarzi and her team, and the Digital Art Exhibition by conceptual digital artist Ecem Dilan Köse.

A presentation by textile artist Gül Bolulu showed that pretty much any natural material can be processed into three-dimensional textiles. In her own weaving workshop, she experiments with plants such as moss, red algae, pine cones, corn, reeds, wheat, barley, zucchini, mushrooms, “sea silk” from mussels and even bones. In a second approach, she has used aloe, roses, palms, avocados and hollyhock, with sugar cane as a dye. After successful fibre production, she is currently experimenting with the production of yarns.

For the second time, there was also the BlueBlackDenim area in Hall 7 with market leaders such as Bossa, İsko, İskur and Kipaş. In an area dedicated for seminars, visitors could find out more about denim trends 2025, as well as new opportunities in textile exports, the Digital Product Passport, the influence of marketing on the denim industry and next-gen denim fibres.

Sustainability, the ’new normal’?

Sustainability efforts were also displayed at many booths; collective efforts being highlighted in the “Hall of Impact” - an installation by exhibitors who want to shape a more sustainable future with their products. Here, there were approaches to waste reduction through 3D design technology, water savings of up to 50 percent in production, a reduction in CO2 emissions, water-saving dyeing techniques, energy-efficient production facilities and recycling processes for textile waste.

The biodegradability of fibres and fabrics is also becoming increasingly important; here, too, some exhibitors presented innovations made from linen, cupro, cotton, lotus, bamboo, coffee beans, cactus, bast, soy, pineapple and coconut fibres.

Maritas Denim, for example, presented a regenerative cotton project in southeastern Turkey and uses its own solar energy. Karafiber has set itself the goal of removing more carbon from the atmosphere than it produces in the areas where it operates. Among other things, its Ecocell Lyocell fibre is obtained from sustainably grown wood and produced in a closed loop to conserve resources.

Fabric mill Aydin Örme presented Lilacell Lace, an innovation made from Tencel's cellulose fibre Lyocell and fabrics made from recycled nylon, while Istanbul-based wool manufacturer Bahariye has officially committed to sustainable, social and environmentally friendly production, which has been certified. Polyester fibre manufacturer Korteks has achieved a breakthrough in Turkey with its polymer recycling plant, which produces polyester yarn from plastic bottles.

Denim manufacturers are also focusing on brown cotton, using the natural colour, or the recycled fibre colour, which is bluish. “We like to use the natural colour of the fibres, which is more sustainable because there is no dyeing process involved and one saves water and energy,” explains B. Hande Yildirim, sales manager at Bossa. The textile group also recycles the water used in the manufacturing process and reuses it.

“We are very surprised at the range of products on offer at Texhibition and are delighted with the focus on sustainability. We have found many interesting products for our business,” summarised Maria Adelaida Velasquez Mejia, director of Linea Directa from Colombia.

The fact that the "green" transformation of the fashion industry is currently at the top of the agenda in all areas of the fair was also evident in the choice of seminar topics - for example, on the Digital Product Passport, circular value chains, and the keynote speech by Marwa Zamaray, the European Climate Pact Ambassador, on "Be Ready for Sustainability Regulations: Time is running out". The Turkish Exporters' Assembly (TIM) and the Turkish Ministry of Trade also highlighted the need for a green transformation of the industry in their speeches and presented support measures.

Is Turkey ready for the Digital Product Passport?

A panel discussion on the Digital Product Passport made it clear that Turkey is currently making great efforts to meet the EU’s Green Deal requirements - after all, it needs to remain competitive. This should not be difficult as the world's fifth largest textile supplier and with a 16 percent share of textile imports into the EU.

The first step, however, is to collect accurate information on environmental data, carbon emissions, solid waste and chemicals; the latter is supported by the REACH regulation. Oeko-Tex 100 will also serve as a guideline. Each product will receive a unique ID through which its circularity can be determined, including the proportion of recycled raw materials. This data is important for customs, among other things, where it is determined whether a product is over the threshold and cannot be exported or whether an additional tax is levied.

In a subsequent step, a common software needs to be developed and introduced. The Turkish Ministry of Industry and Trade and İTKİB will support the creation of working groups. “Traceability is very important and the data should be collected in one place,” advises İTHİB board member Besim Özek. He recommends investing in IT as well, as “manual data collection will not work in the long run”.

However, a representative of Turkish-owned fashion company LC Waikiki is sceptical about the readiness of manufacturers. “Apart from the large companies, they are not ready yet - maybe 20 percent are, but 80 percent are not.” To address this issue, the ministry is offering support in the form of the Responsible Programme, which will introduce a label as a way to show company efforts. In addition, Digital Transformation (DDM) centres will be set up with various partners, and the AB/IPA 111 programme, which deals with life cycle assessments, will be launched next year.

There is also the collaborative initiative Cirpass, which aims to pave the way for digital transformation. “We have been informing supplier companies for two years now and helping them to draw up action plans that can be implemented step by step. It is important that the data is not only collected, but also integrated into their systems,” explains Arzu Konyali, global sustainability director at LCC Waikiki. The company is helping them with training, for which it has received positive feedback. “There is less confusion now,” confirms Konyali.

Marwa Zamaray, European Climate Pact ambassador, is also optimistic about Turkey's preparations for sustainability regulations, calling the country “the most compatible supplier for Europe by far” in her keynote speech. She cited the fact that Turkey has already been practising sustainability in recent decades, while competitors such as China, Bangladesh and India are many steps behind. “This is a huge advantage that makes Turkey a very desirable supplier for European companies,” said Zamaray.

The way forward

A panel discussion on the last day on “Circular value chains in the fashion industry” shed much light on the way forward for Turkey as a sourcing and innovation destination. For Rui Pereira, vice president of sales at start-up Smartex, which uses AI for textiles, a lack of perspective when it comes to collaborations needs to be tackled. “The industry has to shift to be more welcoming to innovations like ours. Technically, we are still in the Industrial Revolution age while other industries such as pharmaceuticals, for example, are already in 2024,” he remarked.

For him, it does not pay to be price-competitive and maybe one cent cheaper than one's neighbour. Rather, a focus on competitive clusters is needed to beat competition from countries like Vietnam, China and Bangladesh. “We need more of a vision in Turkey of a textile hub,” he said, in addition to “a big global fashion brand originating from Turkey”.

Kadir Cesur, circular business development manager at Circulose (formerly Renewcell), pointed to the fact that a product is not more expensive because it is sustainable but because of operating at small scale. Thus for him, it is all about innovative thinking. “People do not pay enough attention to brands that have a positive impact on the environment. Instead of promoting sustainable companies and products that cost more money, there should be a new product or category with sustainable becoming the ‘new normal,’” he suggested.

Spinning that yarn a bit further (pun intended) when asked how feasible it would be to establish such new category, Pereira pointed to the fact that innovations are designed from the ground up. “First, we focus on a problem - waste, for example . Whatever solution will come will be a sustainable solution. It is important to get everyone on board.”

Pereira also drew attention to artificial intelligence (AI): “Initially, there was skepticism; doubt that AI would ever work with textiles. But digitisation is an opportunity, the market is huge,” he said, adding, "don't be afraid to be the lonely guy in the disco dancing. If you dance well, people will join you.”

Serkan Bayir of knitted fabric manufacturer Ekoten pointed out that Turkey is in a unique position geographically, bridging two continents and also cultures. “Information sharing is more important in such a place,” he believes and recommends finding out what the strengths and weaknesses are in terms of innovations. He mentioned diversifying and joint fault-detection as something that worked in his four years of collaborating with Smartex. “It is not about dealing with customers or clients but with colleagues. Ultimately, everyone is doing the same. This will help the manufacturing industry in Turkey and the brands.”

In the end, better quality, less water usage and better productivity is required. “The collaborative aspect is important. And sustainability should be synonymous with product development,” summed up moderator Jyotsna Gopinath from Fashion for Good.

The next Texhibition Istanbul will take place from 5th to 7th March 2025.

FashionUnited was invited to attend Texhibition.

https://fashionunited.uk/news/fairs/denim-dpp-and-durability-texhibition-charts-its-course-ahead/2024092577757